Videojet DataFlex 6320 Thermal Transfer Printer

Videojet that is the most common brand of the world in the industrial printing market is the producer of inkjet, thermal transfer and laser devices which many producers also prefer in our country. As Odak Kodlama, we are selling consumables, spare parts for Videojet inkjet printers, second-hand devices with 2 years warranty and providing the best technical service through our expert technical team. We are the first and only company of Turkey which is able to provide all services, has the broadest staff and background as an alternative to Videojet brand.

Our technical team undergoing regular training for all models of Videojet thermal transfer inkjet printers is providing technical support by phone and other communication means and direct service in your organization for providing your production to continue at any day and time of the year without being interrupted.

Videojet has a product portfolio which can offer many different model thermal transfer solutions together for assisting you to determine proper printing solutions for all your requirements, with an experience longer than 20 years.

Videojet thermal transfer inkjet printers have been designed for high productivity throughout the long working times and keep your production line in uninterrupted operating state. Different models varying by the production scale provide longer operating time and higher resolution thanks to developed software they have; they can print many variable codes for different materials, flexible packages and labels in a clear way.

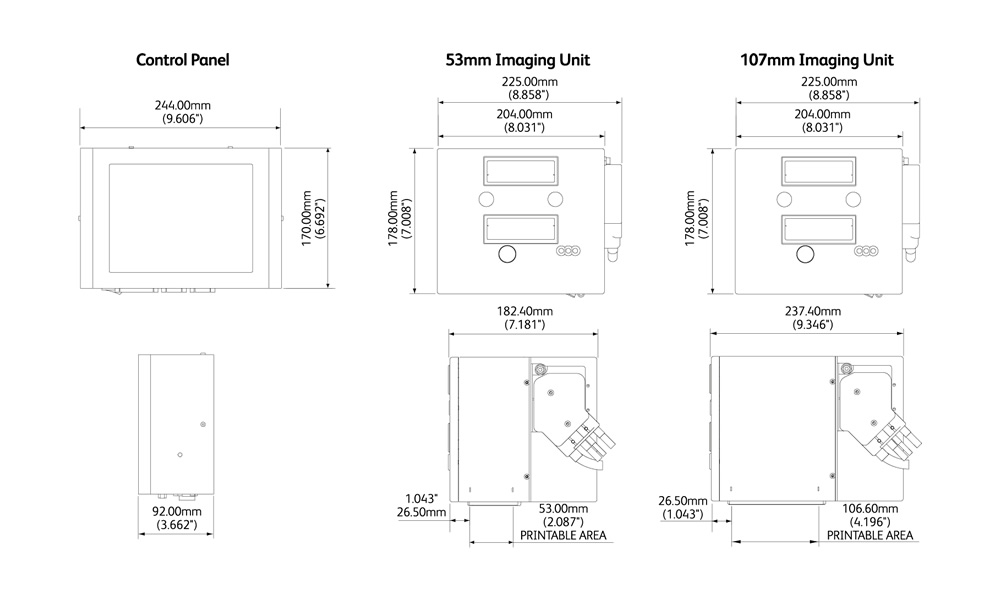

The developed printhead technology in Videojet thermal transfer printers provides your information to be printed to be clear and understandable; it enables you to experience a regular performance with automatic calibration and modular designed printhead unit. You can print the date, time, barcode or complicated material information at high resolution onto flexible film packages with different printhead options in width of 32mm, 53mm and 107 mm and enable your production line to operate with high performance.

Videojet thermal transfer printers print on flexible package and labels at high resolution and correctly; decrease the production’s run-down times and costs in ribbon replacement processes. The ability of Videojet thermal transfer printers to operate at high printing speed for many applications and ribbon options in long ribbon height provide advantages such as ease of use and detection of predictable faults. All of Dataflex product lines have been specifically designed for fast, easy, high performance and productivity.

Ease of Use

A fast and easy ribbon replacement is performed thanks to the ribbon cassette with lock mechanism embedded in Videojet thermal transfer printers. This characteristic decreases the run-down time of production and costs in continuous operating lines; correct printing of products is provided in a fast, easy and faultless manner by means of an interface designed simply. Thanks to a developed software, you can enter the printing data via the screen or you can design your code and logo requirements with your personal computer and import to device. The colored touch screen and printing unit have been designed for operating in a way of fast, faultless and resistant to demanding production conditions.

Production Productivity

Double-way operable, multi-stage and sensitive engines in the printhead unit supervise the use of ribbon effectively and inter-coding spaces are kept minimum. Thus, the ribbon consumption and waste would be reduced. The ribbon cassette with lock mechanism provides an easy and fast ribbon replacement; it reduces the run-down time of the production and costs in continuously operating lines. Bluetooth connection in many models allows the operator to use printers via mobile phone.

Code Guarantee and Fault Proofing

A special software in Videojet thermal transfer printers enables you to make a print preview on the screen prior to printing. Faults which may arise from operator are prevented by an internal code and time info is printed in the product instantly thanks to the option of real-time production date info. All these options provide the correct code to be printed in correct product.

A code quality controller that is a popular special software minimizes the faulty printing probability or re-printing operations without entailing any external hardware, training and technical equipment. Videojet Dataflex printers have an excellent software providing the correct code to be in correct product in an uninterrupted way in all production processes.

Productivity and Advantage of High-Level Operating Time

Videojet thermal transfer printers have been specifically designed for the purpose of minimizing the production halts which will be caused by ribbon replacement and ribbon ruptures. A ribbon cassette design that is about 1200 meters provides you to replace less ribbon within the operating time and lower interruption in the production.

| TECHNICAL SPECIFICATIONS | REMARKS |

|---|---|

| Printhead | 53 mm or 107 mm, 300 dpi (12 points/mm) |

| Printing area | 53 mm Intermittent Printing mode: 2,1 inch (53 mm) width x 3,0 inch (75 mm) length

53 mm continuous printing mode: 2,1 inch (53 mm) width x 11,8 inch (300 mm) length 107 mm intermittent Printing mode: 4,3 inch (107 mm) width x 3,0 inch (75 mm) length 107 mm continuous printing mode: 4,3 inch (107 mm) width x 11,8 inch (300 mm) length |

| Minimum printing speed | Intermittent mode: 10 mm/s

Continuous mode: 0,04 inch/s (1 mm/s) |

| Maximum printing speed | 53 mm intermittent printing mode: 31,5 inch/s (800 mm/s)

107 mm intermittent printing mode: 23,6 inch /s (600 mm/s) Continuous mode: 1.000 mm/s |

| Maximum production | 553 mm normal printing mode: up to 500 prints per minute

53 mm high production volume mode: Up to 700 prints per minute 107 mm normal printing mode: Up to 450 prints per minute |

| Printing specifications | Fully downloadable font support by using TrueType® fonts (including multi-language and Unicode support); fixed, variable and unified text areas; flexible date/time formats; flexible shift code formats; automatic expiration date calculations and privilege management; calendar rules; automatic increasing decreasing text, counters and barcodes; more than one graphic formats are supported (to the maximum printing area); connection of areas to database; scalable text and text blocks |

| Barcodes | EAN 8, EAN 13, UPC-A, UPC-E, Code 39, EAN 128, Code 128, ITF, RSS (including 2D complicated codes), DataMatrix, QR; others are provided upon request |

| Operator interface | TFT SVGA 800x480 full colored LCD and touch screen, Printing preview as it seems, internal diagnosis, 3 password protection levels, extensive language support |

| Ribbon variety | All wax/resin and resin ribbon types |

| Maximum ribbon length | Lengths up to 1.200 meters depending on ribbon content and color |

| Ribbon width | 53 mm: 0,8 inch (20 mm) minimum, 2,2 inch (55 mm) maximum

107 mm: 2,2 inch (55 mm) minimum, 4,33 inch (110 mm) maximum |

| Nominal space between consecutive prints | 0,5 mm |

| Ribbon saving features | Radial, comparative, intermittent strips |

| Image design software | Videojet CLARiSOFTTM, CLARiSUITE® or VideojetConnectTM

Design Pattern Management software |

| Network management software | CLARiSOFT™ |

| Remote printer configuration software | CLARiTY™ Configuration Manager

“Offline” configuration and parameter storage are available as a standard |

| Standard downloading options - manager/follower configuration | Up to four Videojet DataFlex® 6530 printers are controlled by a single CLARiTY control unit |

| Web browser mode | Control Videojet DataFlex® 6530 units over main packaging machinery interface |

| External communication | RS232, double Ethernet, USB memory stick and browser support, Binary and ASCII communication protocols, Windows® drivers, ZPL and SATO emulations |

| External input/outputs | 3 PNP input

2 relay outputs and 2 PNP +24 V output |

| Power source | 100-240 VAC |

| Operating temperature | 0-40 °C2 |