Videojet Thermal Transfer Overprinters

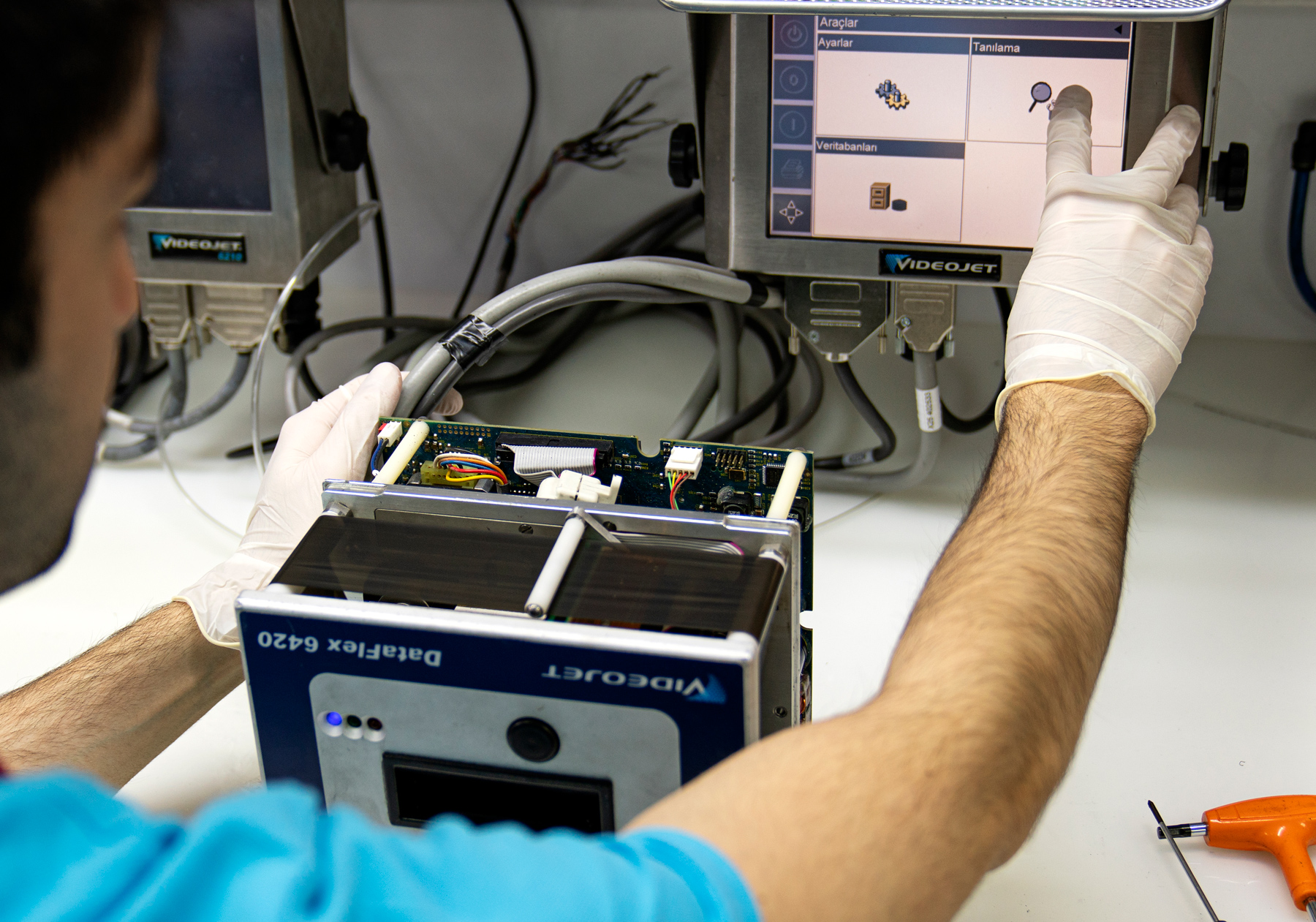

Videojet has a product portfolio which can offer many different model thermal transfer solutions together for assisting you to determine proper printing solutions for all your requirements, with an experience longer than 20 years.

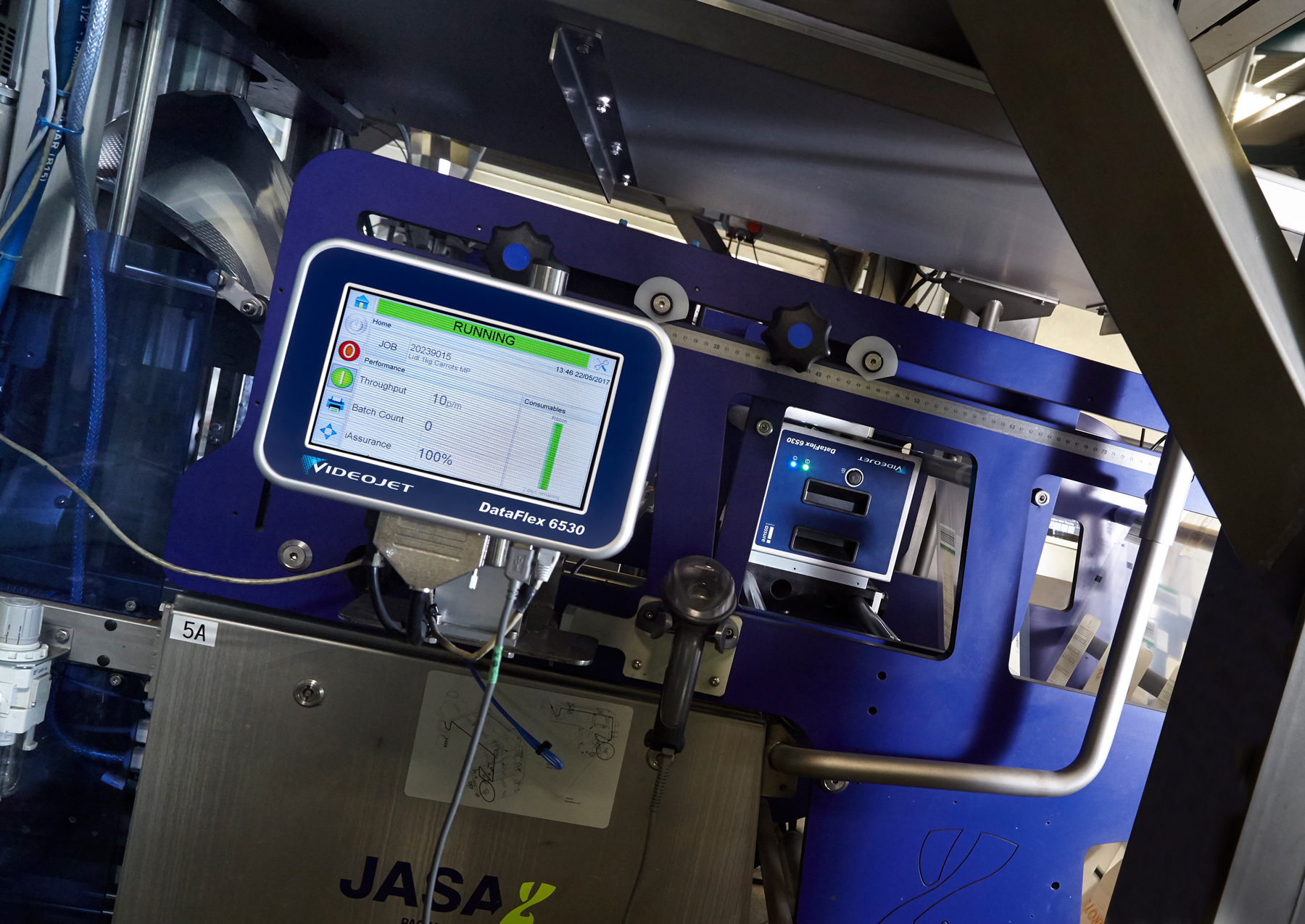

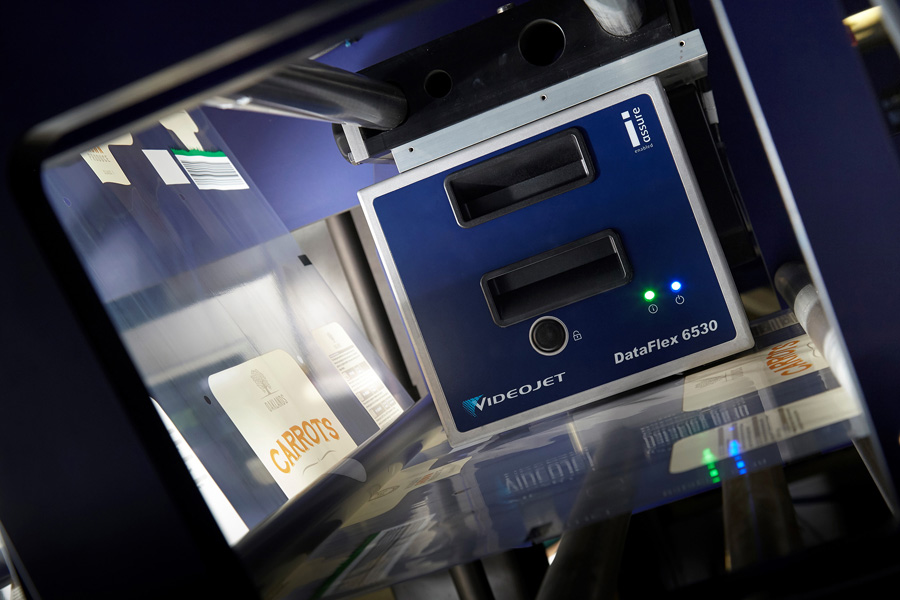

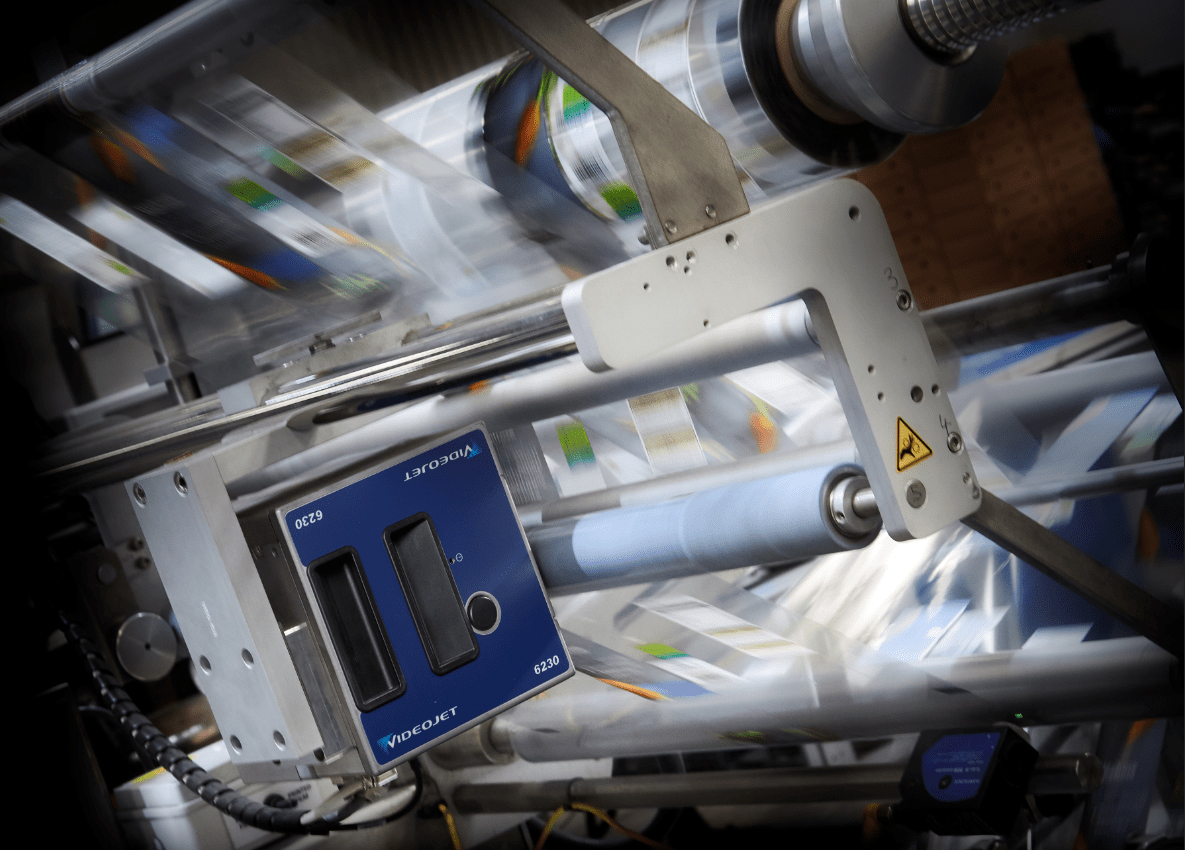

Videojet thermal transfer printers have been designed for high productivity throughout the long working times and keep your production line in uninterrupted operating state. Different models varying by the production scale provide longer operating time and higher resolution thanks to developed software they have; they can print many variable codes for different materials, flexible packages and labels in a clear way.