Blackdot® Ribbons for Videojet Thermal Transfer Machinery

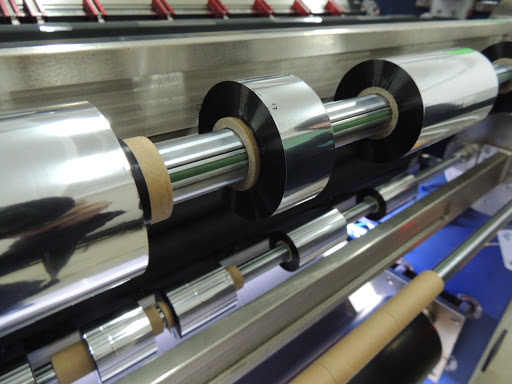

High-quality raw materials which Blackdot® Chemical Corporation use provide optimum printer performance in Videojet thermal transfer printers. Blackdot® ribbons offer a broad product range designed in such a way which will provide an excellent printing quality and can be used in flexible packaging applications.

Blackdot® ribbons have been designed and produced for optimizing the performance in Videojet thermal transfer printers. Ribbon and machinery compatibility provides advantages such as better printing quality, less ruptures, not leading to printhead faults, best adhesion to label and flexible packages.