Videojet 1220 Inkjet Printer

Videojet that is the most common brand of the world in the industrial printing market is the producer of inkjet, thermal transfer and laser devices which many producers also prefer in our country. As Odak Kodlama, we are selling consumables, spare parts for Videojet inkjet printers, second-hand devices with 2 years warranty and providing the best technical service through our expert technical team. We are the first and only company of Turkey which is able to provide all services, has the broadest staff and background as an alternative to Videojet brand.

Videojet has a product portfolio which can offer many different model inkjet solutions together for assisting you to determine proper printing solutions for all your requirements, with an experience based on longer than 40 years.

Videojet 1000 series continuous inkjet printers have been designed for high productivity throughout the long working times and keep your production line in uninterrupted operating state. The developed droplet separation technology in Videojet 1000 series inkjet printers provides your information to be printed to be clear and understandable; it enables you to experience a regular performance with automatic installation, automatic calibration and modular designed printhead.

We are selling consumables, spare parts, second-hand devices with 2 years warranty for many inkjet models such as 1220, 1510, 1520, 1610, 1620, 1710 produced by Videojet that is the most common brand of the world in our market and we are providing the best technical service through our expert technical team. We are the first and only company of Turkey which is able to provide all services, has the broadest staff and background as an alternative to Videojet brand.

Our technical team undergoing regular training for all models of Videojet inkjet printers is providing technical support via phone and other communication means and direct service in your organization for providing your production to continue at any day and time of the year without being interrupted.

Core Maintenance carried in Easy and Planned Terms

The developed core unit designed by expert engineers enables the maintenance period in Videojet 1000 series inkjet printers to be carried out with a proper planning. 1000 series inkjet printers show a longer performance and minimize the productivity loss in the production by means of predictable maintenance periods.

Correct Product Printing with Developed Printing Quality

The developed droplet separation technology in Videojet 1000 series inkjet printers dynamically runs for coding your products in the most correct way clearly and understandably. The temperature and viscosity changes perceived by means of many sensors embedded onto device are instantly followed by the actual working conditions. The ink viscosity is calibrated by the results obtained from these data and a correct printing is provided in any environment.

Printhead, Cabinet and Environment do not get dirty

Spills of ink and make-up are prevented by smart cartridges that are specifically designed for Videojet 1000 series inkjet printers and it is provided every drop of liquid in the cartridge to be used. With the microchip placed on the cartridge, the use of proper consumable is guaranteed by the machinery model and product to be printed. The needle and septum providing direct viscosity between the ink tank and cartridge prevent the inner of device and external environment from getting dirty by preventing the liquid spills.

Compatible Operation with Developed Production Systems and Flexible Connections

Videojet 1000 series printers that are able to operate with the developed production systems harmonically are easily managed over a central computer or user interface without needing a separate interface. You can store more than 250 messages by means of an additional memory which can be used by device memory and USB. You can connect to a web-server for remote access in some models of Videojet 1000 series inkjet printers, you can make your production management being independent from time and place.

Modular and Developed Printhead Unit Design, Porous Printhead

Modular and developed printhead units produced for Videojet 1000 series inkjet printers run with Nozzle in diameter of 50, 60 and 70 microns in such way which will prevent the contamination and enable the correct codes to be produced. For each ink drop produced during printing to reach the product in a stable manner, the extraneous air and dusts are prevented via positive air produced by an internal pump. Dust accumulated in printhead cover is discharged by means of positive air porous design and any ink accumulation that may cause contamination in the printhead would be prevented. The printhead operates with a sustainable performance via the automatic cleaning system and positive air; an easy and fast start-up is provided after the long-term power-off periods. Videojet 1000 series printhead units reduce the printhead contaminations which cause other inkjet printers to make wrong printing and provide less cleaning process and longer operating time without requiring operator’s intervention.

| TECHNICAL SPECIFICATIONS | REMARKS |

|---|---|

| Line speed ability | printing 1-5 lines at a speed up to 533 fpm (162,5 mpm) (10 characters per inch, single printing line) |

| Font matrix configuration | Single line: 5x5, 5x7, 7x9, 8x12, 11x16, 17x24, 34x34

Double line: 5x5, 5x7, 7x9, 8x12, 11x16 Triple line: 5x5, 5x7, 7x9 Four-line: 5x5, 5x7 Five-line: 5x5 |

| Linear barcodes | UPCA and E; EAN8and13; Code128 A,B and C; 2 per hour, as low as 4ml

UCC/EAN 128; Code 39; Code93; Comparative 2 / 5 |

| DataMatrix codes | 10x10, 12x12, 14x14, 16x16, 18x18, 20x20, 24x24, 34x34 |

| Nominal character height | Depending on font, it may be selected in range of 0,079 inch (2 mm) - 0,40 inch (10 mm) |

| Pulse distance | Optimum: 0,472” (12 mm)

Range: 0,197 inch (5 mm) - 0,591 inch (15 mm) |

| Keyboard | Touch-reactive like membrane; 72 digital, alphabetic and special function key. In approximate international PC order, computer-style placement. |

| Screen | 320x240 Bright blue backlighted 5,7" LCD display.

Message composition on WYSIWYG screen |

| Special logo/graphics | It may be created by any user in printer or computer with Videojet Logo Creator software optionally |

| Character sets | American, Arabic, Bulgarian, Chinese, East Europe, Europe, Greek, Hebraic, Hungarian, Italian, Japanese, Japanese/Kanji, Japanese/Katakana, Korean, Russia, Simplified Chinese, Scandinavian, Thai, Traditional Chinese, Turkish, Vietnamese |

| Languages and interface options | English, Arabic, Bulgarian, Czech, Danish, Finnish, French, Deutsch, Greek, Hebraic, Hungarian, Italian, Japanese, Korean, Norwegian, Polish, Portuguese, Russia, Simplified Chinese, Spanish, Swedish, Thai, Traditional Chinese, Turkish and Vietnamese |

| Message Storage | 100 complicated messages; unlimited storage by using USB

Standard USB with Logo and memory backup features |

| Environmental protection | IP55; stainless steel cabinet |

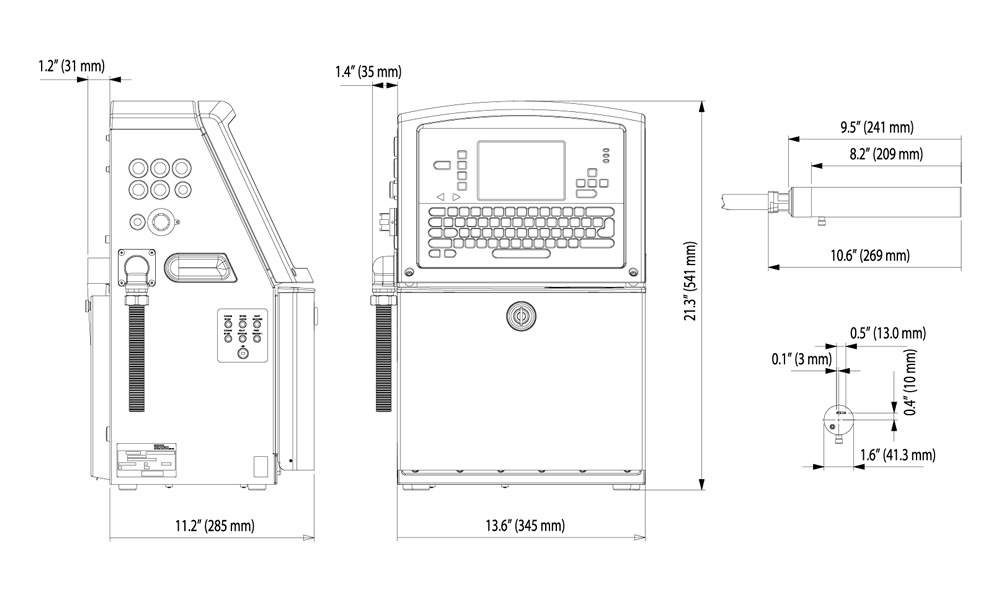

| Printhead | Heated printhead

Diameter: 1,6” (41,3 mm) Length: 9,5” (241 mm) |

| Printer connection cable | Ultra flexible

Length: 6,56’ (2 m)

Diameter: 0,91” (23 mm) Bending diameter: 4,0” (101,6 mm) |

| Mixture liquid consumption | as low as 2,4ml per hour |

| Liquid containers | Ink Smart Cartridge TM 0.793 qt. (750 ml)

Make-Up Smart Cartridge 0.793 qt. (750 ml) |

| Temperature /humidity range | 32°F - 122°F (0°C - 50°C)

0% - 90% RH non-condensing |

| Electrical requirements | Nominal feeding power @50/60 Hz 100-120 / 200-240 VAC, 120 W |

| Approximate weight | In packaged and without ink: 39,68 lb. (18 kg) |

| Options | Positive air pump

Dry air kit for high humidity (requires plant air)

Product detection, relay, RS 485 expansion card RS232, coder, sign lamp expansion card 3 m (9,8-ft) central cable 60- or 70-microns nozzle Food quality version 90-degree printhead Broad accessory range |